3D Printing

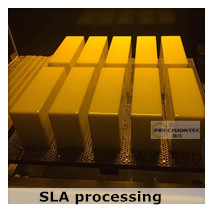

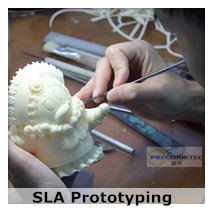

3D Printing can make parts as fast as in 1-2 days with raw materials. If you need high quality surface finishing, it needs more days for polishing, painting,plating and more. We also make SLA master patterns for vacuum casting. We can make big size up to 800mm in only one single piece. With cutting and glued, we can make over two meters big.

What Is 3D Printing? What Is 3D Printing?3D Printing process builds a three-dimensional object from a computer-aided design model, by successively adding material layer by layer with liquid resins, which is also called additive manufacturing. 3D Printing include SLA - Use resin plastic materials SLS - Make PA/Nylon parts Metal Printing - Aluminium & steel |

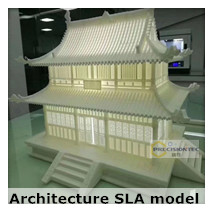

Why 3D Printing? 3D Printing is ideal to make light weight parts and complex features that cannot be made by machining, including industrial design parts,toys,architecture models,art works,sculpture and much more. Short lead-time Competitive price Several materials |

3D Printing materials White resin - Most common and competitive, short lead-time,good surface finishing,heat distortion temperature 45℃ Light yellow resin - Harder than white one, short-lead time, good surface finishing, heat distortion temperature 50-70℃ Grey resin - Hard material,heat distortion temperature 100℃ Transparent resin - Transparent and translucent finishing SLS - PA12, Nylon Metal - Aluminium and stainless steel | |

|

|

|

|

|

Total: 4

Page: 1 / 1

First

←Previous

Next→

End

|