Rapid Prototyping Service

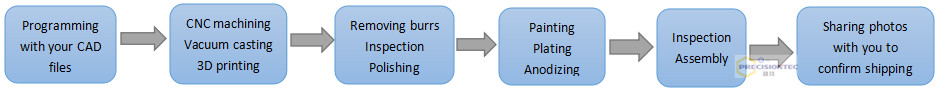

At Precisiontec Limited, we concentrate on making high-quality and low-cost prototypes. From traditional ways to advanced technologies,

we can make your prototypes in a short time.Learn more about prototyping process or send your 3D files to get a free quote for your next project.

What Is Rapid Prototyping? Rapid prototyping is a group of techniques used to quickly produce a scale model of a physical part or assembly using three-dimensional computer aided design(CAD)data. The first methods for rapid prototyping became available in the late 1980s and were used to produce models and prototype parts. Today, they are used for a wide range of application and are used to manufacture production-quality parts in relatively small numbers with short-run economics. All in all, rapid prototyping is the first step to make a design or an idea a reality in a short time, then to do engineering test or make improvements before mass production. |

Why Rapid Prototyping? What can a prototype help you and your business? Here are just some reasons of rapid prototyping: Increase effective communication - By showing your customers or inventors a physical model of your design with high-quality painting and finishing. Decrease development time - By doing rapid prototyping in a short time, and checking appearance,dimensions,structures, then doing improvements and changes if needed. Save your time and money - By testing the market before mass production. Improve the production process - By testing prototypes made in different materials and finishing, and finally choose the right materials,finishing. |

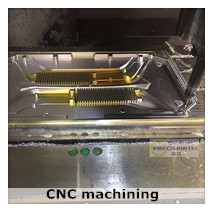

Technologies for Prototyping Service CNC Machining CNC machining is one of the traditional and popular methods for prototyping as it can do machining in wide metal and plastic materials. Your parts can achieve tight tolerance and high quality finishing without making expensive tooling. Machined parts can do high-quality and beautiful surface finishing easily. Learn more... |

Vacuum Casting Vacuum casting also named Silicone Molding is an ideal way to make low volume plastic casing parts in a short time and low-cost. We use Japanese imported resin materials which can make engineering grade plastics and overmolded in multiple materials, including hard plastic and soft rubbers. Lear more... |

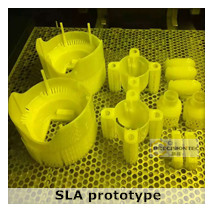

Plastic SLA SLS SLA, now is one of the common ways for making plastic parts in China. Not only it is fast, but it can make in one single piece with complex inside features that cannot be made by traditional manufacturing. We also use SLA to make master patterns for vacuum casting molds. SLA use liquid resin materials and SLS is only used to make PA and Nylon materials. |

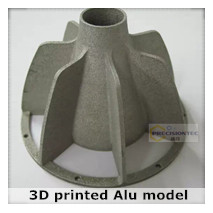

Metal 3D Printing Metal 3D printing is an ideal way for making complex shapes and features that combine light weight with high strength. You do not need to make expensive tooling, and parts can be printed in hours. Lear more... |

What Precisiontec can do for your rapid prototype?

We can make low-cost physical rapid prototypes without surfcae finishing, using a wide range of plastic and metal materials including

magnesium, steel, aluminum, brass,PU, resin, ABS,PC,Acetal(POM),PP,Nylon(PA), PMMA and others you require.

Also we make highly-aesthetic models with high quality surface finishing, like color spray painting, glossy and matte,anodized,plating, sandblasting

and others you need.

We can make small things and big models, like earphones, consumer eletronics, toys, medical devices and equipment, household appliances,vehicle

components, robots and other industrial parts.

Get a quote now.

|

|

|

|

|

Total: 4

Page: 1 / 1

First

←Previous

Next→

End

|