Vacuum Casting Service

At Precisiontec, we a full service from creating master patterns to casting copies, and surface finishing. We will create high-quality models for engineering tests, showroom and exhibitions for your designs. For some special projects, we also make production quality casting parts for marketing and selling. And you will not need to do expensive invest for tooling fees and survive in changing market.

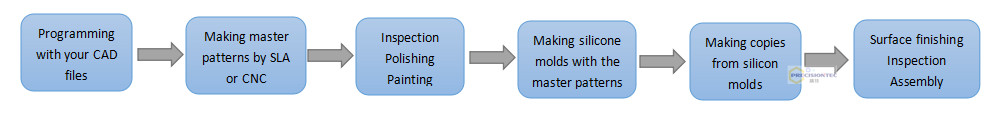

What Is Vacuum Casting? What Is Vacuum Casting?Vacuum casting also named silicone molding as it use silicone to make molds from plastic master patterns of your CAD design .It is a casting process for elastomers using a vacuum to draw the liquid PU material into the silicone mold and doing casting. It is differ from injection molding as its mold life is short and the molds cannot make copies with much undercuts. One mold will have 10-20 copies usually. It takes about 1 day to make a silicone mold and 2-5 hours to make one copy. Bigger parts needs longer time. |

Why Vacuum Casting? Low-cost for silicone molds Competitive for low volume plastic parts Fast turnaround Variety of PU resin materials are available Copies can make high quality surface finishing |

Vacuum Casting Materials PU, ABS(PU8150/PU8158), Rubber, PC, POM, PP, PA, PMMA Rubber hardness: Shore A 40-90 |

|

|

|

|

|

Total: 4

Page: 1 / 1

First

←Previous

Next→

End

|